Yagnik Road, Rajkot, Gujarat

- GST NO. : 24AADCF2745D1Z2

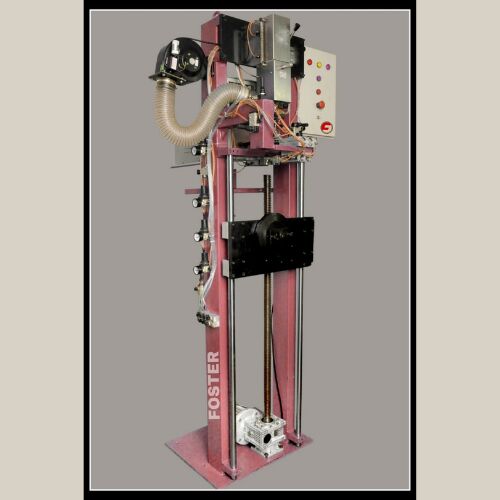

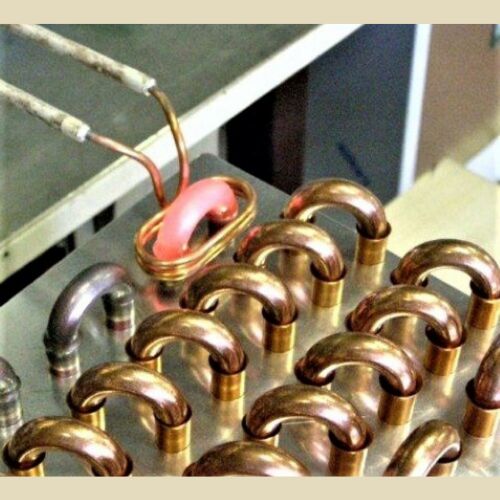

Induction Brazing Machine

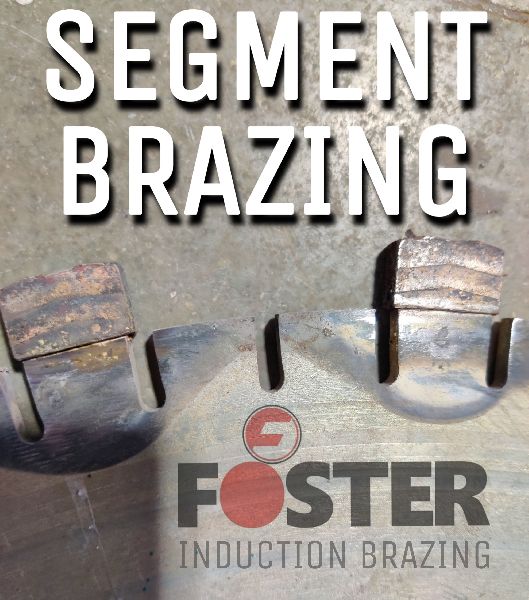

Leading Manufacturers, Exporters, Wholesaler, Retailer of Diamond Segment Induction Brazing Machine, Induction Brazing Machine for Copper Tube Refrigeration, Induction Submersible Rotor Brazing Machine, Induction Tool Brazing Machine and Portable Induction Brazing Machine Copper Wire PIPE from Rajkot.

| Business Type | Manufacturer, Exporter |

| Country of Origin | India |

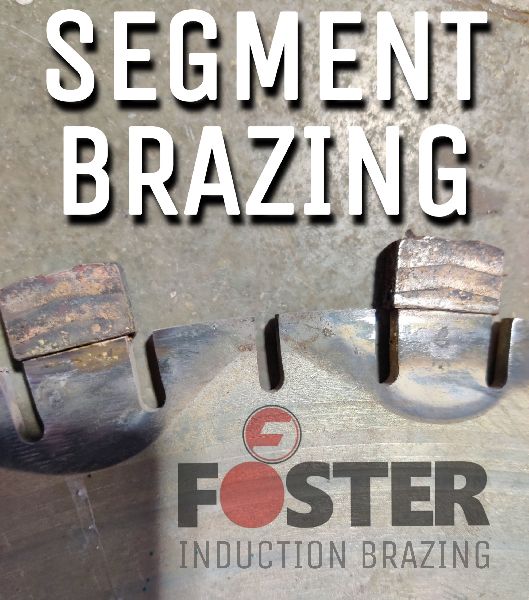

| Type | Diamond Segment Brazing |

| Certification | RoHS |

| Application | For Brazing Material |

| Color | Grey |

| Automation Grade | Semi-Automatic |

| Frequency | High Frequency |

| Port | Mundra |

| Payment Terms | Other |

| Delivery Time | 28 - 30 days |

| Packaging Details | Wooden |

Preferred Buyer From

| Location | Anywhere in India |

Foster Induction Pvt Ltd offer a wide range of Induction Diamond Segments Brazing Machine which can be custom designed for brazing of all kinds of carbide or diamond segments/tips on all kinds of circular or straight saw blades. These products are manufactured using quality tested raw material under the supervision of our quality inspectors which ensures their high accuracy/ repeatability in brazing process and manufacturing Brazing Equipment. And Induction Brazing process is more reliable safe and cost effective than any other conventional method. Our product is available with the 'flexible extension coil' which is more suitable to your desired Brazing Operation.Semi-Auto Circular Saw Blade Segment Brazing Machine stand available for Blade Dia. From 300mm to 1500mm and 600mm to 2500mm

| Business Type | Manufacturer, Exporter |

| Country of Origin | India |

| Certification | ISO 9001:2008 |

| Application | For Brazing Material |

| Weight | 85 -100 kg |

| Color | Grey |

| Voltage | 440V, 230V AC |

| Condition | New |

| Automatic Grade | Semi Automatic |

| Power | 12-15kw, 9-12kw |

| Driven Type | Electric |

| Warranty | 1year |

| Brand Name | Fostar |

| Machine Type | Induction - IGBT |

| Usage | Copper brazing |

| Size | Compact 2*2 |

| Port | Mundra |

| Payment Terms | Other |

| Delivery Time | 28 - 30 days |

| Packaging Details | Wooden |

Preferred Buyer From

| Location | Anywhere in India |

Foster Induction Brazing is a metal joining process that uses a filler metal and usually an anti-oxidizing solvent called flux to join two pieces of close-fitting metal together without melting the base materials.

Induction brazing is precise and quick. Only narrowly defined areas are heated, leaving adjacent areas and materials unaffected. Correctly brazed joints are strong, leak-proof and corrosion resistant. They are also very neat, usually requiring no further milling, grinding or finishing. Induction brazing is ideal for integrating into production lines.

Brazing, Welding, Soldering of

Condenser copper tubing; Evaporator copper tube; Compressor copper pipe; Transformer motor wire; Fridge and air conditions on-line tube; Other on-line copper pipe etc.Induction Brazing Offers Numerous Benefits.

Throughput: induction generates heat only in the portion of the part needed

Better efficiency

Better quality with less part distortion

Repeatability: after the coil and heating process are defined, you can count on a precise, consistent quality braze every time

Easy integration: into a lean manufacturing process

Safety: no open flame

Additional Information:

Production Capacity: 10

| Business Type | Manufacturer, Exporter |

| Brand Name | Foster |

| Driven Type | Electric |

| Color | Grey, White |

| Condition | New |

| Automatic Grade | Semi Automatic |

| Power | 18-21kw, 21-25kw |

| Application | Induction Rotor Brazing |

| Certification | CE Certified, ISO 9001:2008, RoHS |

| Voltage | 440V |

| Type | Brazing Machines |

| Weight | 85 -100 Kg |

| Warranty | 1year |

| After-Sales Service Provided | As Per Warranty |

| Country of Origin | India |

| System | Induction - IGBT |

| Output Current | 0-100 A |

| Brazing Diameter | V3 / V4 / V6 / V9 |

| Chilling Type | Cooling Tower |

| Phase | 3 Phase |

| Rotor Size | V3 / V4 / V6 / V9 |

| Port | Mundra |

| Payment Terms | Other |

| Delivery Time | 28 - 30 days |

| Packaging Details | Wooden |

Preferred Buyer From

| Location | Anywhere in India |

Features & Benefits :

- Operator controls Easy to operate, no need for skilled operator

- Durable and compact design, loaded with safety features

- Low maintenance, easy to install and move

- Adopts the latest IGBT power units and frequency conversion control techniques with high efficiency, low energy consumption and higher output.

- Constant current and power control function providing higher reliability, sustainability and increased productivity.

- Hassle-free maintenance and minimal downtime.

- Advanced controls with diagnostic features.

- Improved production values through higher melting rates with homogeneous Melting due to auto stirring technology.

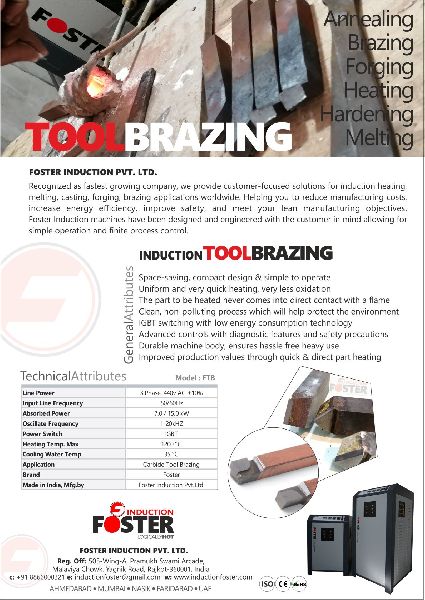

| Business Type | Manufacturer, Exporter |

| Country of Origin | India |

| Certification | CE Certified, ISO 9001:2008, RoHS |

| Application | Tool brazing |

| Weight | 85 -100 kg |

| Color | Grey, White |

| Voltage | 440V |

| Condition | New |

| Automatic Grade | Semi Automatic |

| Power | 12-15kw, 15-18kw, 21-25kw, 9-12kw |

| Driven Type | Electric |

| Warranty | 1year |

| Brand Name | Foster |

| Machine Type | Induction - IGBT |

| After-Sales Service Provided | as per warranty |

| Automation Grade | Semi-Automatic |

| Output Current | 0-100 A |

| Brazing Diameter | As per the Job Size |

| Phase | 3 Phase |

| Duty Cycle | 100% |

| Cooling Water Pressure | 2 to 4 Bar |

| Port | Mundra |

| Payment Terms | Other |

| Delivery Time | 28 - 30 days |

| Packaging Details | Wooden |

Preferred Buyer From

| Location | Anywhere in India |

Induction brazing is a process in which two or more materials are joined together by a filler metal that has a lower melting point than the base materials using induction heating. There are specific reasons to use induction heating for industrial brazing. These include selective heating, better joint quality, reduced oxidation and acid cleaning, faster heating cycles, more consistent results and suitability for large volume production.Induction heating can be targeted to provide heat to very small areas within tight production tolerances. Only those areas of the part in close proximity to the joint are heated; the rest of the part is not affected. Foster Induction heating produces clean, leak proof joints by preventing the filler from flowing in areas that it shouldn't flow. This ability to create clean and controllable joints is one of the reasons that induction brazing is being used extensively for high-precision, high-reliability applications.Because the induction heating cycle is very short in comparison to flame brazing, more parts can be processed in the same amount of time, and less heat is released to the surrounding environment. “An induction brazing system quickly delivers highly localized heat to minimize part warpage and distortion.Foster Induction brazing system is a very repeatable and accurate process because variables such as time, temperature, alloy, fixturing, and part positioning are very controllable. The internal power supply of the RF power supply can be used to control cycle time, and temperature control can be accomplished with pyrometers, visual temperature sensors or thermocouples.Brand : FOSTER, 100% Make in India

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Portable Copper Pipe |

| Certification | Iso 9001:2008,Ce Certified,RoHS |

| Weight | < 50 Kg |

| Color | Grey |

| Voltage | 230/420V |

| Condition | New |

| Automatic Grade | Automatic, Fully Automatic, Semi Automatic |

| Power | 12-15kw, 15-18kw, 18-21kw, 21-25kw, 7-9kw |

| Driven Type | Electric, Mechanical, Pneumatic |

| Warranty | 1year |

| Country of Origin | India |

| Brand Name | Foster,Foster |

| Application | Induction Copper Tube Brazing |

| After-Sales Service Provided | as per warranty terms |

| System | Induction - IGBT |

| Automation Grade | Semi-Automatic |

| Power Source | Electric |

| Frequency | High Frequency |

| Features | Easy to move, Easy to operate |

| Size | Compact |

| Port | Mundra |

| Payment Terms | Other |

| Delivery Time | 3 - 5 Working Weeks |

| Packaging Details | Wooden |

Preferred Buyer From

| Location | Anywhere in India |

Brazing is a metal joining process that uses a filler metal and usually an anti-oxidizing solvent called flux to join two pieces of close-fitting metal together without melting the base materials.

Induction brazing is precise and quick. Only narrowly defined areas are heated, leaving adjacent areas and materials unaffected. Correctly brazed joints are strong, leak-proof and corrosion resistant. They are also very neat, usually requiring no further milling, grinding or finishing. Induction brazing is ideal for integrating into production lines.

Brazing, Welding, Soldering of Condenser copper tubing; Evaporator copper tube; Compressor copper pipe; Transformer motor wire; Fridge and air conditions on-line tube; Other on-line copper pipe etc.

Numerous Benefits Of Induction Brazing :

Throughput: induction generates heat only in the portion of the part needed

Better efficiency: Better quality with less part distortion

Repeatability: after the coil and heating process are defined, you can count on a precise, consistent quality braze every time

Easy integration: into a lean manufacturing process

Safety: no open flame

Quality: FOSTER, 100% Make in India

CUSTOMIZED SOLUTIONS ARE OUR SPECIALTY

NEED A QUOTE

SPEAK TO OUR

SALES ENGINEER TODAY.